Exploring the Secret Benefits of Membrane Layer Switch Over in Cutting-edge Layouts

In the realm of item style, the integration of membrane layer changes offers notable advantages, especially in terms of sturdiness and reliability. These buttons, constructed with split, versatile products, withstand rigorous conditions and recurring usage, a vital advantage for devices revealed to extreme environments.

Boosted Longevity and Dependability

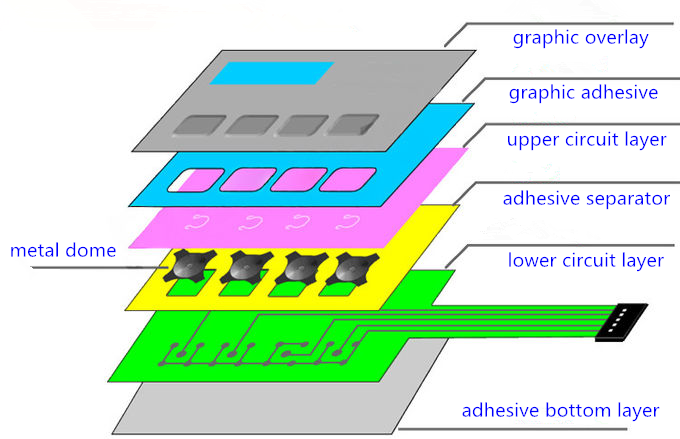

Membrane layer buttons are renowned for their boosted resilience and dependability, associates that stem from their one-of-a-kind building. These switches are composed of layers consisting of a graphic user interface layer, a conductive ink circuit, and a dielectric layer, all secured versus environmental aspects such as moisture and dust. Membrane Switch. This layering not just secures the interior elements but additionally ensures that the switch functions under an array of unfavorable conditions

Membrane layer switches likewise operate successfully in a large range of temperature levels and are resistant to resonances, making them suitable for usage in both commercial and consumer applications where dependability is important. Membrane Switch. Their robust construction leads to fewer failures and upkeep demands

Modification and Visual Adaptability

Past their architectural benefits, membrane switches deal extensive modification and visual adaptability to satisfy diverse style needs. Designers can tailor these interfaces to specific customer requires with a variety of sizes, forms, and shades. The graphic overlay, which is the leading layer of a membrane layer switch, can be published with customized graphics, logos, and message, making each application distinct while sticking to brand name standards. This degree of customization boosts user interaction by incorporating user-friendly style components that are very easy and visually appealing to navigate.

Furthermore, the capability to integrate clear home windows for LEDs or lcds and responsive functions such as embossing improves the user experience. These alternatives permit the development of a multi-dimensional user interface that is not just functional yet also adds to the general item appearances. By leveraging these customization abilities, suppliers can produce unique items that stand out in open markets.

Cost-Effectiveness and Reduce of Combination

Moreover, the thin and versatile nature of membrane layer switches allows for straightforward combination right into various applications, from advanced medical equipment to consumer electronics. Their compact design does not need complicated setting up treatments, consequently reducing installation time and costs. In addition, membrane layer buttons work with countless substratums and adhesives, boosting their flexibility across different markets. These assimilation capacities not just streamline the style process but likewise speed up the product development cycle, making it possible for faster time-to-market for brand-new innovations.

Verdict

To conclude, membrane layer switches stand out as a durable choice in innovative styles, providing improved toughness and dependability essential for sustaining severe problems. Their capability for personalization supports a large range of visual preferences, making them functional for different branding needs. In addition, their cost-effectiveness and simplicity of assimilation help with swift and efficient item development, positioning membrane layer changes as more information a very beneficial option for designers aiming to stabilize functionality, style, and bankability in affordable markets.

In the realm of item layout, the integration of membrane changes offers noteworthy benefits, specifically in terms of toughness and reliability.Beyond their structural advantages, membrane layer switches over deal extensive personalization and visual adaptability to meet diverse style demands.While modification boosts visual allure and usability, membrane switches likewise offer considerable expense advantages and simplicity of combination that profit suppliers and end-users alike. The production procedure for membrane changes entails less products and much less labor contrasted to typical mechanical buttons, which straight equates into lower production expenses.In verdict, membrane layer changes stand out as a robust option in innovative layouts, supplying boosted durability and reliability essential for enduring harsh problems.